This Food Hub is located in the Kamuli district, in the eastern part of Uganda. In 2020, it registered a population of 558,500 people.

Generally, Ugandan diets are mainly composed of starch staples especially cereals and roots, tubers and bananas, with legumes being the main protein source. Currently, the food environment is characterized by a transitioning diet manifesting elements of both Westernized and traditional diets, even though the diet remains predominantly plant-based.

The prevalence of stunting, wasting and being underweight among children under the age of five years (under-fives) stands at 29%, 4% and 11% respectively. At the national level (entire population), the prevalence of underweight, stunting and wasting stands at 41%, 27% and 4% respectively.

Approximately 24% of females of reproductive age and 9% of males aged 15-54 years are either overweight or obese.

Vitamin A and iron deficiency are the most common micronutrient deficiencies.

The crops with the most important agricultural production in Uganda are maize (76.2% of farmers produce it), bean (65% of farmers) and coffee (23%).

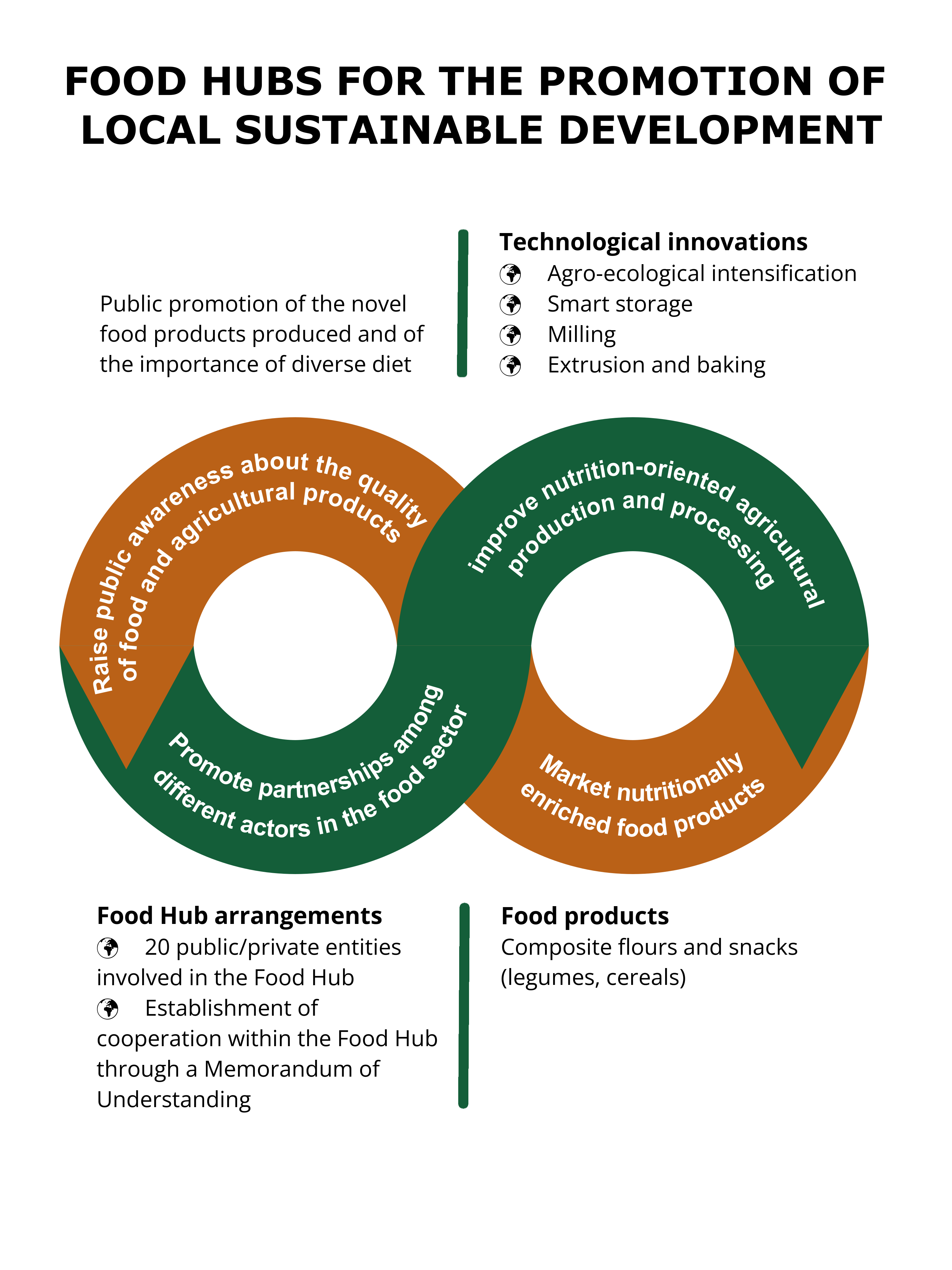

Highlights about the work carried out in this Food Hub

Technological innovations in this Food Hub

Agro-ecological intensification. The idea is to introduce combined agroecological practices to allow the use of limited land to produce multiple, and profitable crops achieving ecological and economic sustainability, preserving soil conditions, and reducing waste while saving inputs. Gardens planted with crops that provide balanced diets will be designed. The objective is to introduce among farmers the practice of dietary planning right from the time of crop planning and provide them with guidelines for the production of nutritionally diverse crops on limited land.

Smart storage systems. The intelligent system developed in Morocco for humidity and temperature control using connected sensors will be adapted and tested in this Food Hub for protecting stored maize and beans from vermin.

Milling. The overall objective is to produce blended flours with improved nutritional and functional properties. Legumes and cereals blended flours will be produced from local food raw materials and characterised according to their physicochemical and nutritional properties. Their sensory properties, shelf-life stability and microbial analysis will also be determined.

Extrusion and baking. The overall objective is to process different locally available foods into novel convenient nutrient products, such as nutrient-dense flours that have the potential to address nutritional gaps, nutrient-dense snacks that have the potential to substitute low nutritional value snacks, and nutrient-dense noodles from locally produced foods. The nutritional and physicochemical properties of the developed food products will be determined. Product formulations will be developed using locally produced nutritionally rich foods. These will include cereals (maize/sorghum/millet), pulses (common beans) and oil seeds (soybeans/sesame) for all Food Hubs. Additionally, orange-fleshed sweet potatoes, pumpkins and grain amaranth will be used in this Food Hub. The final products’ nutritional value, physicochemical properties, storage stability and sensory acceptance will be analysed.

Highlights about the research with farmers

FoodLAND surveyed a total amount of 400 farmers in this region with the aim of improving the background knowledge of African smallholder farmers’ decision-making and of individual and contextual conditions. 182 out of these 400 farmers surveyed were women, and the other 218 were men. 75.2% of farmers are members of any local farmers’ associations.

According to the information gathered from the surveys, 95.5% of farmers’ income is lower than the average income in the region, the income of 4% of farmers is about the average or somewhat higher, and only 0.5% of farmers stated an income higher than average. Nevertheless, 85.9% of them are able to meet their household’s food needs, 11.5% experience some difficulties, and 2.5% face serious food shortages.

Besides, they have reported major worries regarding the near future about health diseases (4.34 on a scale from 1 to 5), infestation pests (4.30), the cost price increase of fertilizer or seeds (4.26), social problems (violence or crime) (4.23), income reduction (4.04), drought (4.02), loss of farm job (3.74), and food shortage starvation (3.65).

With regard to their interest and propensity to introduce new technologies and/or productions, 96.4% of farmers are extremely or moderately interested in adopting a technological innovation (4.90 on a scale from 1 to 5).

Highlights about the research with consumers

With the aim of enlarging background knowledge of African consumers’ food preferences and behaviours and of their socioeconomic drivers and measuring the current level of dietary diversity, FoodLAND has assessed food consumption at both individual and household levels that provide a good measure of diet quality and diversity. FoodLAND has conducted surveys both in households and out of stores in Kalerwe, which is paired with this Food Hub. 500 people participated in the survey. Below you can find some highlights extracted from these surveys, regarding consumers’ preferences, habits, incentives, and barriers when it comes to choosing food products for their households.

Parallel to the survey instruments, a series of incentivised economic behavioural experiments were developed to gain insights into consumers’ conscious and non-conscious decision-making processes. During the experiments, participants were asked to make decisions on the use of assigned tokens, which were going to influence both their final earnings and the earnings of one or some other participants.

In order to also collect data on rural consumers’ socio-economic conditions and socio-demographics (e.g., migration), food provisioning, preparation and consuming habits and community conditions and services, while paying attention to the gender perspective, a series of surveys with randomized samples of rural consumers have also been conducted in this Food Hub. 500 pairs of women of reproductive age and one of their children between 6 to 23 months of age participated in the survey.